History:

1978 - creation of company

1980 - creation of tool-room

1985 - first EDM electro-erosion machine

1989 - first CNC miling machine

1990 - first CAD/CAM system

1990 - first WireCut electro-erosion machine

1990 - first contract for the automotive industry

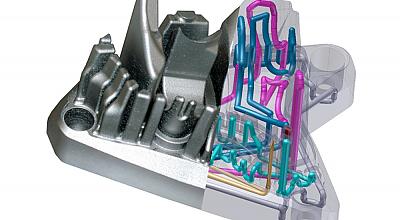

1995 - first 2-components mould

1999 - ISO 9001 certificate

2004 - first mould above 10 tons

2006 - first mould above 15 tons

2011 - first mould about 30 tons

2011 - new production department with 20 tonnes gantry

2011 - purchase of a new multi processing Mazak machine

2011 - purchase of gantry milling machine HARTFORD HEP-3150 SG

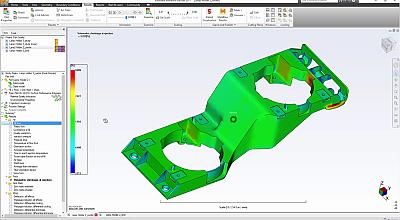

2012 - purchase MoldFlow, Simulation Mechanikal software

2013 - purchase of NX CAM and CAD software

2013 - purchase of new machinery:

- IXION TLF 1004 4-AXIS

- MAHO DECKEL DMU 125T

- MAHO DECKEL DUO BLOCK 100P

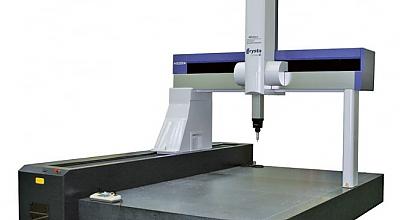

Group of highly skilled engineers underlies design and technological department. Many years of experience and continuous search of new solution, particularly in connection with advanced CAD/CAM/CAE systems, gives results in reduction of time and cost of mould fabricating.

Prototypes

We support our clients to opportunity for making of prototypes:

- FDM

- SLS

- SLA

- Silicon moulds

- Moulds from aluminum